Saturday 30 May 2015

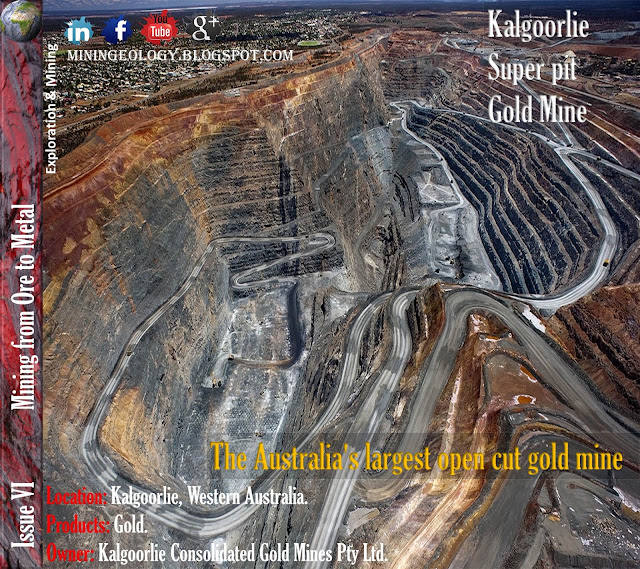

Kalgoorlie Superpit Gold Mine

The Australia's largest open cut gold mine

Location: Kalgoorlie, Western Australia.

Products: Gold.

Owner: Kalgoorlie Consolidated Gold Mines Pty Ltd.

Overview: The Super Pit is located off the Goldfields Highway on the south-east edge of Kalgoorlie, Western Australia. The pit is oblong in shape and is approximately 3.5 kilometres long, 1.5 kilometres wide and 570 metres deep. At these dimensions, it is large enough to be seen from space.

The Super Pit is owned by Kalgoorlie Consolidated Gold Mines Pty Ltd, a company owned 50/50 by Barrick Gold Corporation and Newmont Mining Corporation. The mine produces 850,000 ounces (28 tonnes) of gold per year, and employs around 550 employees directly on site.

Originally consisting of a number of small underground mines, consolidation into a single open pit mine was attempted by Alan Bond, but he was unable to complete the takeover. The Super Pit was eventually created in 1989 by Kalgoorlie Consolidated Gold Mines Pty Ltd.

Barrick Gold acquired its share of the mine in December 2001, when it took over Homestake Mining Company. Newmont became part-owner of the mine three months later, when it acquired Normandy Mining in February 2002.

Geological Setting: Most of the good gold mined in the Super Pit occurs within ore lodes formed by ancient shears in a rock unit called the Golden Mile Dolerite. The gold mining area of Kalgoorlie-Boulder-Fimiston has long been called the Golden Mile because of the geographical concentration of rich mines in that area, even though the lodes occur in an area over 2 km in width and 1 km in depth.

Kalgoorlie Terrane.

1. Pre- to syn-D, granitoids were emplaced as broadly conformable sheet-like bodies at the base of, or within, the greenstone succession, probably during

2. Post-D, to syn-D, granitoids were diapirically emplaced, and are concentrated in a zone along the western side of the Kalgoorlie Terrane.

3. Late-tectonic to post-tectonic granitoids were emplaced late in the history of the Terrane. Limited geochronological data suggest the granitoids were emplaced at 2690-2680 Ma (group I), 2665-2660 Ma (group 2) and 2650-2600 Ma (group 3) (Hill ef al.,

1992). Small porphyry intrusions, including lamprophyres

(Rock et aL, 1989), are widespread and petrologically diverse; they may be genetically related to some of the I-type granitoid suites (Witt, 1992). They are common in and near regional deformation zones, and are associated with many gold deposits (Perring et al., 1988,1989).

GOLD MINERALIZATION:

All rock types in the Kalgoorlie Terrane host gold mineralization, but most production has come from fractionated quartz-dolerite zones of mafic-ultramafic sills and from tholeiitic basalt.

The dominance of quartz-dolerite and tholeiitic basalt remains even if bias introduced by the "giant" Kalgoorlie deposits (Golden

Mile, Mount Charlotte) is eliminated. A similar picture emerges when host rocks to gold mineralization throughout the Yilgarn Craton are considered (.1B; Groves & Barley, 1988). Quartz-dolerite and tholeiitic basalt host rocks are characterized by high FeO* contents and FeO*/(FeO*+MgO) (Tables II.1,11.2), where FeO* is total iron expressed as FeO. Although mafic rocks are the dominant hosts, other rock types (e.g., granitoids, porphyry, ultramafic rocks) host important deposits, and can even be the dominant host rock on a camp scale (e.g., porphyries at New Celebration). All rock types in the Kalgoorlie Terrane host gold mineralization, but most production has come from fractionated quartz-dolerite zones of mafic-ultramafic sills and from tholeiitic basalt .

Production:

Mining is via conventional drill and blast mining via face shovels and dump trucks. Around 15 million tonnes of rock is moved in any given year, consisting primarily of waste rock.

Gold within the Golden Mile lode system is unusual in that it is present as telluride minerals within pyrite. In order to recover the gold, the ore must be crushed, passed through a gravity circuit to recover the free gold present in some of the higher-grade lodes, and then subjected to flotation to produce an auriferous pyrite concentrate. This is then roasted at a small smelter outside Kalgoorlie-Boulder to liberate the gold from the tellurides, with doré bars poured.

More information and resources

Friday 29 May 2015

Building a GIS Career

08:00

No comments

The use of geospatial technologies is increasingly being used in a variety of fields. GIS is being used in many different industries and the skills required to be a successful GIS professional have evolved over the years. Below are recommendations on building a strong background in preparation for a career in GIS based on what the majority of employers are looking for. However, keep in mind you will find a wide variety of work and educational backgrounds among those working in GIS jobs. This post is a work in progress and will be updated as new skills and achievements are identified as being essential for developing a successful GIS career.

The starting point in building a successful career in GIS is a solid education. This involves taking classes in cartography, GIS, spatial analysis, database management, web technologies, and programming. There are a lot of GIS certificate courses emerging that help solve the confusion as to which classes to take, but any department offering GIS coursework is a great starting point. Start by taking a general “what is GIS” themed course. This is important because it is important to understand the general concepts in GIS before actually attempting some of the functionality. Taking a good cartography course is critical as well. Often overlooked by many seeking GIS knowledge, a comprehension of cartographic techniques is especially important for understanding mapmaking and for learning how to create maps that are effective in communicating geographic data. The end process of visualizing spatial analysis can be tricky. Understand the methods by which one can display data is essential to effectively communicating with maps.

Most employers strongly prefer at least a bachelor’s degree. Depending on the industry of the job listing, that degree would preferably be in Geography, Computer Science, Engineering, or Urban Planning. Job seekers that have a bachelor’s degree in another major should supplement their college education with a certificate program. Those striving for managerial positions in GIS will be more successful if they also have a master’s degree.

Learning GIS Software Applications

The next step is to take coursework that applies the concepts of GIS and cartography. These courses are always software specific so it’s important to choose a class that teaches the software you will be using once employed. Currently, ESRI products dominate about 70% of the GIS software market with MapInfo the nearest competitor. If you are unsure which software to learn, I suggest learning about ESRI’s ArcGIS suite of software, as these are the software applications most often required by employers. You can also do a job search of companies and agencies in the area you want to work in to see what GIS software they are requiring for employment. Classes specific to a GIS software package can be taken at most universities and colleges, through satellite courses from the software companies themselves, or through online or distance learning. ESRI offers free modules online for many introductory courses to their products.

The Next Level

The current trend in GIS is customization and application. More and more GIS packages are being altered to serve a specific GIS purpose. This could range from an Emergency Response System to an application customized to allow a user to generate mailing lists based on a spatially selected area. Many of the software packages contain some ability for customization using programming languages. The type of language will be affected by the software application. There are two different areas of customization: desktop applications and browser based applications. For the browser based mapping applications, understanding the various web-based languages such as HTML, Javascript, ASP and so forth is critical.

Since GIS analysis is involves the integration of spatial and tabular data, some knowledge of relational database management (RDBMS) is a must. Taking a class in SQL (structured query language) is important to mastering RDBMS and understanding structured query language (SQL).

Getting GIS Experience

As with all fields, nothing beats real-world experience. Internships are extremely popular in GIS as they allow the employer a cheap source of labor for lower level GIS tasks and, in turn, provide a valuable training experience for the intern. The only way to truly become proficient in GIS is to simply use it. The coursework will only serve to provide a base knowledge of the field and without some form of practical experience, most companies will not be interested in hiring. To find internships check with your school’s geography or urban planning department. Oftentimes companies and agencies looking for student help will advertise there. You can also directly inquire with places that you are interested in working for. Internships can lead to full-time positions.

Finding a GIS Job

Once you’ve completed your coursework and gotten hands on work experience, where do you look for a job? There are quite a few job sites on the internet specializing exclusively in GIS employment opportunities. So write up a resume and cover letter and hit the internet. Aim for jobs that meet your education and experience level. In general, the hierarchy and required GIS experience for hands-on (i.e. non-managerial) positions is as follows:

GIS Intern

Almost every higher level (Technician, Analyst, etc.) position will require some hand-on job training. The best way to achieve this is through an internship. Internships are mostly low-paying, part-time jobs but they are the best way to get further GIS training and to develop your GIS skills in a real world setting. Learning GIS out of a textbook is a great way to get started, but in reality, few GIS tasks are solved as neatly as the “follow steps 1-10″ of your workbook. Getting an internship has become more competitive in recent years. To be a competitive candidate for an internship, only apply once you’ve taken a solid groundwork of GIS courses especially an “Introduction to GIS” class, a second advance GIS class, a separate cartography class (if available), and a class covering databases. While an internship provides on-the-job training, you will mostly be expected to learn on your own so it’s important to already have a good baseline to start from.

GIS Technician/Specialist

1-2 years hands on experience with GIS based software. If you first took an internship you should be able to aim for these types of jobs. The job titles Technician and Specialist tend to be used interchangeably. They are both journey level positions. GIS Technicians should have a solid grasp on the most common GIS tasks. Examples of those are: the ability to edit vector data, create data in a GIS software application from a multitude of sources (paper documents, Excel files, hand written maps, etc.), be able to work with external databases (such as Access and SQL Server) including understanding structured query language (SQL), understand projections and coordinate systems, work with GPS receivers to collect data, and strong cartographic design skills. While it’s not the only software package out there, a good majority of GIS positions are looking for proficiency in ArcGIS. Having a good grasp on working with KML and KMZ files is also critical as some companies are using Google Maps and Google Earth for some tasks. Common tasks involve cartographic output (mapmaking) and data manipulation. A lot of positions are also starting to look for some basic programming experience.

GIS Analyst

At least 2-3 years experience with GIS based software. At this level you should be performing more complex analyses and RDBMS. In addition, an analysts should also be primarily concerned with application development and should have a fair amount of programming experience (see Learning Programming for GIS). For example, if you work with Esri’s ArcGIS software, python and SQL will be needed. Analysts, having built on their skills developed as a GIS Technician, should have strong skills in cartographic design, analytical geography, database design and management, programming, project management, and communication (including strong writing skills). Supervisory responsibilities and project management are also common responsibilities with the Analyst supervising technicians and interns. There is also a growing demand by employers for Analysts to be knowledgeable about open source GIS.

GIS Coordinator or Manager

Depending on the company or agency, usually the manager has at least 5-6 years of experience in the field. The manager would also be required to have budgetary and project management experience. Depending on the size of the staff, this position may or may not also involved technical responsibilities. At the executive level, having a GIO, a Geographic Information Officer, is emerging as a new position in the GIS field. A GIO is a counterpart to the traditional CIO, Computer Information Officer.

Thursday 28 May 2015

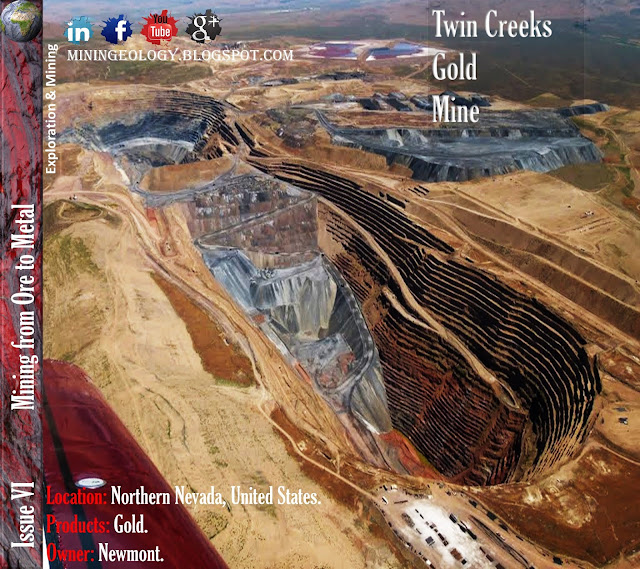

Twin Creeks Mine

08:23

No comments

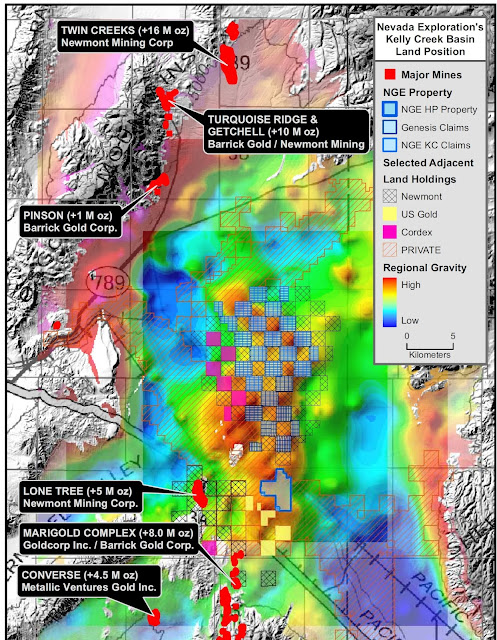

Twin Creeks Mine

Location: Northern Nevada, United States.

Products: Gold.

Owner: Newmont.

Deposit size: Length 4 km

Width 1 km

Area 3 sq km

Deposit features: Beds or lenses

Dikes or sills

Fault zone

Deposit age geologic: Eocene

Intrusive rock: Dacite porphyry

Ore bearing unit: Pennsylvanian–Permian Etchart Fm.; Ordovician Valmy Fm. and Comus Fm.

Ore bearing unit thickness: 3000 m

Tectonic setting: North-American craton rifted western margin, imbricate structure.

Alteration : Contact metamorphism (?) decarbonatization, oxidation & silicification (jasperoid)

Associated deposits: sediment-hosted Au

Discovery date: 1984

Operation types: Open pit, Crushing and milling & Heap leach.

Total tonnage: 223.4tonnes

Contained gold: 484 tonnes

Recovery: Au 80%

Gold grade: 2.67 g/t

Reserves (December 31, 2014): 0.158M oz. gold

BY -Dr.R.N.Mishra-

Nevada is one of the most important metal-mining States of the West and has produced large quantities of gold, silver, and lead. At present her production of precious metals is again rising rapidly, and although the output of lead is much smaller than formerly the State is now an important producer of copper. The mining districts number about 200.

The northern boundary line of Nevada lies within the province of the Columbia River lava, and these flows of basalt and rhyolite extend for some distance into the State. At the bend of the California State line the Sierra Nevada forms the boundary of Nevada and a small part of that great range is included within its limits.

TWIN CREEKS MINE has Sediment-hosted gold deposit in Nevada, U.S.A. The USGS recognised the deposit as Carlin Subtype, manifested as Beds or lenses, Dikes or sills or of Fault zone kind of mineralisation. The Twin Creek Deposit has been surveyed and the dimensions are 4 km long x 1 km wide with an area of 3 sq.km. Generally, The Carlin–type deposits represent some of the largest hydrothermal gold deposits in the world.

The Carlin type deposits show enrichment in the elements gold, antimony, mercury, thallium and barium. This enrichment is created by hydrothermal circulation with a temperature of up to 300 °C. The underlying rocks out of which the minerals are dissolved are normally silty carbonates, although also silicates and other sediments are possible. The material in the deposit is altered in a way that the carbonate minerals are either dissolved or converted to the silicates by silicate rich hydrothermal water. For example dolomite is transformed into jasperoid. Another alteration is the formation of clay minerals by interaction of water and feldspar.

-Dr.R.N.Mishra-

Reference information

Bloomstein, E.I., Massingil, G.L., Parratt, R.L., and Peltonen, D.R., 1991, Discovery, geology, and mineralization of the Rabbit Creek gold deposit, Humboldt County, Nevada, in Raines, G.L., Lisle, R.E., Schafer, R.W., and Wilkinson, W.H., eds., Geology and ore deposits of the Great Basin, Symposium Proceedings: Reno, Geological Society of Nevada, p. 821–843.

Breit, F.J., Jr., Ressel, M.W., Anderson, S.D., and Muirhead, E.M.M., 2005, Geology and gold deposits of the Twin Creeks mine, Humboldt County, Nevada, in Rhoden, H.N., Steininger, R.C., and Vikre, P.G., eds., Symposium 2005—Window to the world: Reno, Nevada Geological Society, p. 431–451.

Briggs, D.F., 2006, Mining operations report, version 2005: Unpublished.

Groff, J.A., Heizler, M.T., McIntosh, W.C., and Norman, D.I., 1997, 40Ar/39Ar dating and mineral paragenesis for Carlin-type gold deposits along the Getchell Trend, Nevada—Evidence for Cretaceous and Tertiary gold mineralization: Economic Geology, v. 92, p. 601–622.

Hall, C.M., Kesler, S.E., Simon, G., and Fortuna J., 2000, Overlapping Cretaceous and Eocene alteration, Twin Creeks Carlin-type deposit, Nevada: Economic Geology, v. 95, p. 1739–1752.

Nevada Bureau of Mines and Geology, 2011, The Nevada mineral industry, 2010: Nevada Bureau of Mines and Geology Special Publication MI-2010, 151 p.

Newmont, 2012, Reserves and non-reserve mineralization: Annual Report of December 31, 2011, 8 p., last accessed May 8, 2012, at http://www.newmont.com/sites/default/files/u87/NEM_2011%20Attributable%20Reserves%20and%20NRM.PDF.

Osteberg, M.W., and Guilbert, J.M., 1991, Geology, wall-rock alteration, and new exploration techniques at the Chimney Creek sediment-hosted gold deposit, Humboldt County, Nevada, in Raines, G.L., Lisle, R.E., Schafer, R.W., and Wilkinson, W.H., eds., Geology and ore deposits of the Great Basin, Symposium Proceedings: Reno, Geological Society of Nevada, p. 805–819.

Simon, G., Kesler, S.E., and Chryssoulis, S., 1999, Geochemistry and textures of gold-bearing arsenian pyrite, Twin Creeks, Nevada—Implications for deposition of gold in Carlin-type deposits: Economic Geology, v. 94, p. 405–422.

Stenger, D.P., Kesler, S.E., Peltonen, D.R., and Tapper, C.J., 1998, Deposition of gold in Carlin-type deposits—The role of sulfidation and decarbonation at Twin Creeks, Nevada: Economic Geology, v. 93, p. 201–215.

Thoreson, R.F., Jones, M.E., Breit, F.J., Doyle-Kunkel, M.A., and Clarke, L.J., 2000, The geology and gold mineralization of the Twin Creeks gold deposits, Humboldt county, Nevada, in Crafford, A.E.J., ed., Geology and ore deposits—The Great Basin and beyond; Geology and ore deposits of the Getchell region, Humboldt County, Nevada: Geological Society of Nevada Symposium 2000, Field Trip 9, p. 85–111.

Tuesday 26 May 2015

Sunday 24 May 2015

Mineral Policy of Australia

00:57

No comments

Australia

The commonwealth of Australia is a highly developed country with world’s seventh highest per capita income. The country is comprised of mainland, Australian continent (7.618 million km2 surface area), surrounded by more than 8000 islands in Indian and Pacific Ocean that includes Tasmania (68,000 km2). The population is estimated to be 22.70 million as on 2011. Australia follows constitutional monarchy with federal parliamentary system of government with Queen Elizabeth II at its apex. Australia has six states and two major mainland territories.

The mineral resource base industries are the key pillar of Australian economy. Australia is the world’s leading producer of bauxite (65 Mt) and iron ore (393.9 Mt), the second largest producer of alumina (19.6 Mt), lead (0.57 Mt) and manganese (4.45 Mt), the third of brown coal (66 Mt), gold (~250 t), nickel (185 kt), zinc (1.29 Mt) and uranium (1.224 Mt U), the fourth of aluminum (2 Mt), black coal (445 Mt) and silver (1.63 kt), and finally the fifth largest producer of tin during 2009.

The mineral policy and mining legislation are largely provincial. Mines and minerals are a state subject in Australia and hence each of the six states and two major territories has their own mining legislation. Although there are many similarities, differences in legislation from state to state are also very significant. The policy framework and Acts are powerful with clarity, efficiency and competitive in the process to make the fortune. But the system is quite complex on certain issues.

The legislation as framed in Western Australia can be considered as model for discussion, with some deviation from other states and territories. The Act may be cited as Mining Act 1978 and updated

2009. The mining tenement or concession includes PL, exploration license, retention license, ML, general purpose lease and miscellaneous license granted or acquired under this Act or by virtue of the repealed Act. The Act includes the specified piece of land in respect of which the tenement is so granted or acquired. The application for all types of license in prescribed format is to be submitted to the office of the mining registrar or warden of the mineral field or district in which the largest portion of the land to which the application relates is situated. The application must be accompanied by the following documents.

(a) Written description of the area.

(b) A map with clearly delineated tenement boundaries and coordinates.

(c) Detail program of work proposal.

(d) Mining proposal or mineralization report prepared by a qualified person.

(e) Estimated amount of money to be expended.

(f) Stipulated fee and the amount of prescribed rent for the first year or portion thereof.

The mining registrar may grant the license if satisfied that the applicant has complied in all respects with the provisions of this Act or refuse the license if not so satisfied. The holder of prospecting and exploration license will have priority for grant of one or more mining or general purpose leases or both in respect of any part or parts of the land while the license in force. The license and lease are transferable.

|

| Western AustraliadTenement Type Summary (2009) |

A Comment By

In recent years all Mining title applications are required to submit a full EIS. The process of undertaking an EIS can take up to three years and cost around $3M. There are not too many juniors out there who can commit such resources before getting into production. Take out the juniors who initiate 90% of new projects and very soon Australian mining will become a duopoly. Our Industry is being killed off by gutless politicians and self serving civil servants; it is well past the time to protest.

Operating Mines in Australia are about 421 mines and project

Friday 22 May 2015

Remote Sensing

00:24

No comments

Inside the Blog Everything about Remote Sensing and GIS for Geologists

Thursday 21 May 2015

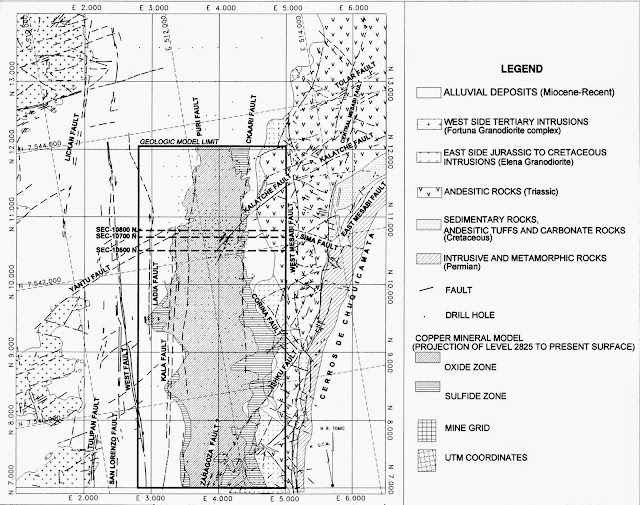

Radomiro Tomic Copper Mine

Radomiro Tomic Copper Mine

Location: 3,000m above sea level in the Atacama Desert of northern Chile

Products: Copper

Owner: CODELCO Production future.

Ore Type: Porphyry copper deposit.

Overview: Radomiro Tomic is the first mine to have been entirely developed by the Chilean state copper-mining company, Codelco. Located at 3,000m above sea level in the Atacama Desert of northern Chile, this new mining and hydrometallurgical operation is 4km from the Chuquicamata mine and smelter. Development was approved in 1995, started in 1996 and was essentially completed in 1997. The initial target capacity was 150,000t/y of copper cathodes but optimisation during construction raised the rating to 180,000t/y by the commissioning date. Prime contractor LX Ltda (Bechtel and ARA in joint venture) completed work early, below the budgeted $641 million. Recovering copper by heap leaching and electrowinning, Radimiro Tomic was inaugurated in 1998. In 1999 Codelco contracted Kvaerner Metals to increase the plant capacity to 250,000t/y of cathode at a cost of $220 million. This expansion was completed in 2001. Codelco initially created a new Radomiro Tomic Division with a streamlined organisation to manage the facility. During 2002, the corporation decided to amalgamate Chuquicamata and RT as one division - Codelco Norte - and developed a consolidated resource exploitation plan for the deposits in this area. About 460 people work at Radimiro Tomic.

Geology of the Deposit: The Radomiro Tomic porphyry copper deposit is located along the West Fissure structural domain, one of the main strands of the Domeyko fault zone (Cuadra and Camus, 1998). The orebody is 1 km wide, elongated north-south, and is completely buried by 30 to 150 m of Tertiary to Quaternary alluvial gravels, below which a thick oxidation zone was developed on granitic bedrock during a semiarid regime.

The host rock of copper mineralization at RadomiroTomic is the Chuqui Porphyry, the youngest intrusion emplaced on the eastern side of a Tertiary intrusive sequence. To the east the Chuqui Porphyry is in contact with a coarse-grained granodioritic intrusion, the Elena Granodiorite, and to the west with the Fortuna Granodiorite Complex (Fig. 2). The latter is a north-northeast–elongated intrusion 22 km long by 5 km wide that comprises five intrusive bodies of fine- to mediumgrained hornblende-biotite granodiorite. This complex, dated 39 to 37 Ma (Dilles et al., 1997) intruded Triassic to early Tertiary andesitic volcanics. Contact relationships between the Chuqui Porphyry and its host rocks are not well defined because information is based only on a few existing drill holes along the margins of the deposit.

The hypogene alteration and mineralization processes are restricted almost entirely to the Chuqui Porphyry, a granodioritic to monzonitic intrusion with medium- to coarse-grained phenocrysts set in a fine groundmass, and they were originated within the West Fissure fault zone. Recent 40Ar/39Ar dating on the Chuqui Porphyry at Radomiro Tomic gives an average age of 32.7 Ma for the K silicate late-magmatic phase and an age of 31.8 ± 0.3 Ma for the sericitic alteration (Cuadra et al., 1997). These ages define a slightly different hydrothermal timing compared to Chuquicamata (33.4 and 31.1 Ma, respectively; Zentilli et al., 1995). At Radomiro Tomic, potassic alteration is younger and the quartz-sericitic event is older than at Chuquicamata, so the time duration of alteration is shorter at Radomiro Tomic than at Chuquicamata.

The mineralized intrusion is buried beneath Tertiary to Quaternary alluvial gravels, with a thickness ranging from 30 m on the east side to 150 m on the west side. As a result the bedrock surface has a relatively gentle slope to the west, with some abrupt changes indicating possible faults, but this is not well-defined yet. The gravels are composed of angular andesitic fragments, 1 to 10 cm in diameter, in a sandy and poorly to moderately cemented matrix. This unit is in direct contact with the underlying leached or oxide zones of the deposit. Locally, the gravel is mineralized with exotic copper reaching thicknesses of tens of meters, mainly along northwest-trending paleochannels according to the paleotopography. A tuff intercalated in the gravels, 2 m below the current surface, was dated in biotite by the K-Ar method at 9.7 ± 0.7 Ma (Cuadra et al., 1997).

Alteration

K silicate alteration is developed pervasively throughout the entire Radomiro Tomic deposit, with the highest intensity found in the area between coordinates 10,000 N and 11,000 N (Fig. 2). It is represented typically by quartz-K feldspar veinlets and biotitization of hornblende phenocrysts. Quartz-sericitic alteration is less abundant and is clearly controlled by northeast- and north-south–striking subvertical structures. These structures are marked by quartz-pyritechalcopyrite D-type veins, with quartz-sericite halos. In the upper part of the oxidation zone supergene argillic alteration is defined by montmorillonite and kaolinite in fractures and as replacement of feldspars.

Hypogene mineralization

Hypogene mineralization follows a concentric distribution of inner bornite-chalcopyrite, intermediate chalcopyrite > pyrite, and outer pyrite > chalcopyrite zones centered around the coordinates 9,700 N and 11,000 N (Fig. 2) and averaging 0.5 wt percent total copper. Minor molybdenite mineralization is present alone or associated with chalcopyrite and pyrite in quartz veins and veinlets striking north and dipping subvertically. Arsenic minerals such as enargite are absent in significant contrast to the Chuquicamata orebody. This difference may indicate a greater degree of erosion for the Radomiro Tomic orebody. Hypogene mineralization continues to at least 400 m below the top of sulfides.

Supergene mineralization

Supergene oxidation and leaching processes affected the hypogene mineralization to an average depth of about 200 m beneath the gravel-bedrock contact (Fig. 3). Supergene mineralization is present immediately below the gravels with a typical vertical distribution of leached oxide zones, a mixed (oxide sulfide) zone, and a secondary sulfide zone. Locally, along quartz-sericite-faulted veins enrichment has reached depths of up to 800 m. The description of the different zones follows.

|

| Fig. 2. Surface geology of the Radomiro Tomic area. The shaded area represents the subsurface geologic projection of the orebody at level 2,825 m. |

Copper Mining

The conventional open pit strips at a 1.5:1 waste-to-ore ratio using rotary drills, P&H 4100 shovels, a LeTourneau loader, Caterpillar 793B and Komatsu 330st-capacity trucks. An FFE Minerals gyratory primary crusher near the pit rim supplies coarse ore, which travels to the main processing area via a 9,615t/h Krupp conveyor. The expansion added tertiary cone crushing (SRP Hydrocones) to the secondary Symons cone. Conveyors take stockpiled ore to pre-treatment and stacking on the racetrack-style heap-leach pads. Leached material is reclaimed by a bucket wheel and is conveyed to the dump area. Rahco and MAN-Takraf supplied the crawler-mounted materials-handling equipment. To handle the expanded production, the conveyor drives were fitted with programmable soft braking systems.

Copper Processing

Following acid leaching, the copper is separated from the heap-leach solution by four-stage solvent extraction with Acorga reagents and is fed in solution to the electrowinning tankhouse for recovery as cathodes using sophisticated technology. Four solvent-extraction trains designed and supplied by Outokumpu Engineering (including VSF mixer-settlers, Proscon 2100 NT process control system and OTI 99 titrators) remove the copper. The electrowinning feed and reagent streams are cleaned using molecular sieve coagulators and electrolyte filters designed by Codelco, and by CPT flotation columns. The large and highly automated electrowinning tankhouse was fitted with unique cathode cranes and stripping machines as well as a system of blowers and aerosol chimneys to ventilate the cells. The expansion added 272 cells, two travelling cranes and a cathode washing-stripping machine. Secondary leaching of waste will add 24,000t/y to 28,000t/y of copper to the cathode output.

Copper Production

After start-up, Radomiro Tomic recorded total operating costs of $0.44/lb, producing 162,000t copper in 1998 and 190,100t in 1999. The expansion boosted output to 256,000t/y in 2001 and Codelco hoped to maintain production at around 300,000t/y thereafter. Actual output in 2002 was 297,119t at a cash cost of $0.33/lb.

References

- Economic Geology 96, 401-420 (2001).

- Cameron, E.M., Leybourne, M.I., and Palacios, C. (2007): Atacamite in the oxide zone of copper deposits in northern Chile: involvement of deep formation waters? Mineralium Deposita 42, 205-218.

- Cameron, E.M., Leybourne, M.I., and Palacios, C. (2007): Atacamite in the oxide zone of copper deposits in northern Chile: involvement of deep formation waters? Mineralium Deposita 42, 205-218.

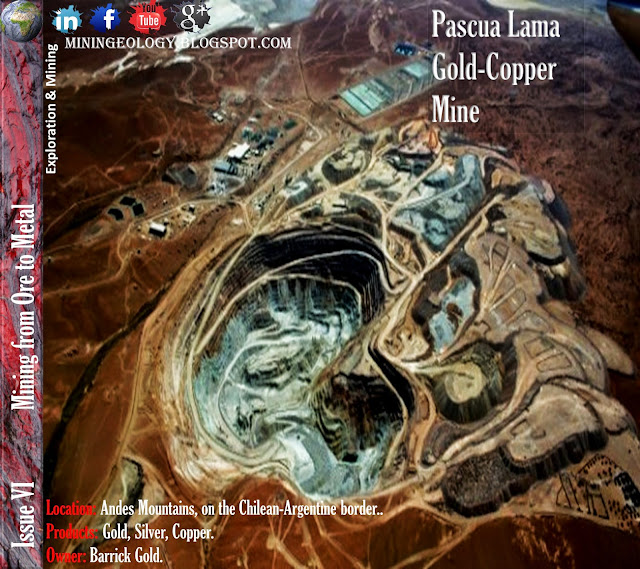

Pascua Lama mine

|

| Pascua Lama mine |

Location: Andes Mountains, on the Chilean-Argentine border.

Products: Gold, Silver, Copper.

Owner: Barrick Gold.The Mine life: The mine life is expected to be 25 years.

Deposite Type:

The gold, silver and copper mineralisation and alteration assemblages at Pascua-Lama are associated with a structurally controlled acid sulphate hydrothermal system hosted by intrusive and volcanic rock sequences of the Upper Palaeozoic and Middle Tertiary age. Alteration and mineralisation are of the high-sulphidation, epithermal type. Throughout the Pascua-Lama district, the alteration and mineralisation appear to have been strongly controlled by structure. This control is most evident along the Esperanza, Pedro and Quebrada de Pascua fault systems. As is typical with high-sulphidation epithermal deposits, the principal metal commodities at Pascua-Lama are gold and silver, the copper content is sub-economic.

The presence of hypabyssal intrusive host rocks that are not related to mineralisation is unusual for high sulphidation deposits, making Pascua-Lama (along with Barrick’s Alto Chicama deposit in Peru, which is hosted by meta-sedimentary rocks) somewhat unique among deposits of this type.

Overview

Pascua-Lama is located at an altitude of 3,800m to 5,200m. The Chilean part of the mine constitutes 75%, while 25% is located in Argentina. The development activities of Pascua-Lama were stopped in April 2013, following a Chilean court's orders on issues of sanitation and violation of the Glacier monitoring plan. The Diaguita indigenous community filed a petition for the closure of the project. Barrick Gold's plea to reopen the project was rejected by a local appellate court in Copiapó, Chile, on 24 April 2013.

The Chile's Supreme Court, however, issued a ruling in September 2013 overturning the Copiapó court order. Following the ruling, Barrick Gold will construct a water management system at the Chilean section of the mine in order to receive environmental approval for the project. The water management system is expected to be completed by the end of 2014.

Barrick Gold announced its decision to temporarily suspend the Pascua-Lama project, in October 2013, in order to reduce its debt burden. Construction of facilities required for obtaining the environmental approval will, however, be completed. The company plans to resume the mine's development in future.

The Argentinean segment was to include critical infrastructure such as the processing plant and tailings storage facility.

Barrick Gold had estimated the development capital cost of Pascua-Lama to be $3bn at 2009 prices, but the construction delay increased the estimated capital costs of the project to approximately $8bn to $8.5bn at 2012 prices. The development of the mine would have created more than 5,500 jobs during construction and more than 1,600 jobs during production phase.

Geological Setting

The Pascua-Lama deposit is situated at the crest of the high cordillera of Region III, along the international border between Chile and Argentina and on the northern edge of a major mineralised trend known as the El Indio belt. This trend, along which a number of major precious metal deposits are located (including the nearby Veladero mine), stretches 47km south of Pascua-Lama to the world-renowned El Indio deposit and adjacent Tambo deposit (both closed).

The geology in the region is dominated by extrusive volcanic rocks that are locally intruded by hypabyssal stocks of varying size and numerous dikes and sills (Figure 6-1). Volcanic activity began with deposition of the Permian Guanaco/Zonso felsic ash flows from a caldera 15km east of Pascua-Lama and subsequent intrusion of the Permian-Triassic Chollay crystalline felsic rocks along the extent of the El Indio belt. These events were followed by intrusion of the Triassic Pascua-Lama granite complex in the immediate vicinity of the Project. Deposition of extrusive volcanic rocks and continued intrusive activity resumed in the Oligocene with the Bocatoma diorite stocks (33-36Ma), the Tilito dacite ash flows (27.2-17.5Ma) the Escabroso mafic andesite and andesitic flows (21.0-17.5Ma), and the Cerro de Las Tortolas I andesites (16.0 ±0.2 -14.9 ±0.7Ma), after which volcanic activity decreased markedly in the vicinity of the El Indio belt. Subsequent activity was confined to the Vacas Heladas intermediate dacitic domes, lava flows and felsic tuffs (12.8-11.0Ma), and the Late Miocene rhyodacite dikes at Pascua. The most recent activity in the region included deposition of the post mineralisation silicic Vallecito rhyolites south of Pascua-Lama in the vicinity of Cerro de Las Tortolas, and the Upper Pliocene Cerro de Vidrio rhyolite. All ages are from Bissig et al., (2000a & 2001) and Martin et al.,(1995).

Regional structure in and around the gold deposits and prospects in the El Indio belt is dominated by northerly-trending high angle reverse faults, normal faults and fold belts oriented parallel to the major structural grain of this portion of the Andean Cordillera. Pascua-Lama is positioned near the center of a northerly trending graben that contains nearly the entire Tertiary volcanic sequence that is distributed along the spine of the cordillera in Chile and Argentina. This graben is bounded by two high angle reverse fault zones, the Baños del Toro/Chollay located 10km west of the deposit and the El Indio zone situated 16km to the east. The graben is cut at Pascua and El Indio by strong, west-northwest fracture zones, which form loci for mineralisation. Large elliptical fracture zones are also present immediately to the east and/or northeast of both El Indio/Tambo and the Pascua-Lama/Veladero deposit areas, and these zones may have contributed to host rock permeability.

Metallurgy and Mineral Processing

The Pascua-Lama (and Esperanza) ore is extremely complex and highly variable, ranging from relatively straight forward oxide zones which are amenable to cyanide leaching, to highly altered sulphide zones containing soluble sulphate minerals with some cyanide-amenable gold/silver and some refractory gold/silver hosted in sulphides. The majority of silver occurs in an enriched blanket of secondary mineralisation in the upper zones of the deposit with silver grades typically four to five times those of the underlying primary zones.

The deposit is hosted in a high-sulphidation hydrothermal system consisting of acidic material that requires a washing stage to remove soluble iron and copper sulphate salts that are detrimental to subsequent processing. Ore material in the deposit is classified as two main types:

Non-Refractory and Refractory, both ore types are crushed, wet ground and washed in similar circuits. The washed Non-Refractory ore is subject to direct cyanide leaching only with pregnant solution which is recovered from the counter current decantation (“CCD”) circuit, treated in a conventional Merrill Crowe (zinc precipitation) circuit to produce gold/silver doré. The washed

Refractory ore is subject to flotation with cyanide leaching of the flotation tails. Solution recovery and precious metal production from the leached tails is via the CCD and Merrill Crowe circuits to produce gold/silver doré. The flotation circuit produces a final gold/silver rich concentrate of nominally 12% copper for export to smelters.

The proposed nominal plant capacity is 45,000t/d of ore, 30,000t/d for Non-Refractory ore and 15,000t/d for Refractory ore, according the following schedule:

• Year 1, Q1: Two lines, 30,000t/d Non-Refractory ore;

• Year 2, Q4: Three lines, 45,000t/d Non-Refractory ore; and

• Year 3, Q3: Two lines, 30,000t/d Non-Refractory ore and one line, 15,000t/d Refractory ore.

Mine Production and Mineral Reserve Estimate

SRK audited the Mineral Reserve estimate that was prepared by Barrick (Table 2). SRK is of the opinion that the estimation strategy and methods employed meet or exceed current industry standards and the reserves have been classified according to CIM guidelines. The LoM plan was based on calculations prepared in mid-2008 for the Feasibility Study and not the end of year Mineral Reserve estimate disclosed in this report.

The difference between the LoM plan and the Mineral Reserve estimate is not considered material to Silver Wheaton.

Mining commences in 2011 with pre-stripping. The amount of pre-stripping required is 66.4Mt and this is scheduled to be mined in an 18-month period using the owner’s equipment. The first ore is produced in late 2012. The production phase commences in 2013. The LoM production schedule is shown in Table 3.

The average ore plus waste mining rate is 66.0 Mt/y, comprising 18.3Mt/y of ore and 48.8Mt/y of waste. The average overall strip ratio is 2.71:1, exclusive of the pre-production period. The average overall strip ratio inclusive of the pre-production period is 2.88:1.

.jpg)