Location: Agnew, Western Australia.

Products: Gold.

Owner: Gold Fields Limited.

Mineral Resources at 3.5 Moz.

Mineral Reserves at 1.2 Moz.

Life of Mine extends to 2019 (7 years).

Licence status and holdings

The agnew gold mining company proprietary limited (agmc), can 098-385-883, was Incorporated in australia in 2001 as the legal entity holding and conducting mining activity on the Agnew mineral leases. The gold field’s limited group holds 100% of the issued shares of AGMC Through its 100% holding in the issued shares of orogen holding (bvi) limited. Agnew controls Exploration and mineral rights over a total area of 57,836 hectares (total of granted tenements) and has security of tenure for all current exploration and mining leases that contribute to future Mineral reserves.

Operational infrastructure

One underground complex, mining from two separate ore bodies (kim south and main north)accessed via declines. Centralised administrative office, engineering workshops and one cip processing plant (1.3 mtpa capacity).

Deposit type

Orogenic greenstone gold deposits hosted in a number of different styles of lodes. Although all of the agnew deposits broadly occur at the intersections between structures and stratigraphy, there are subtle differences in alteration and mineralisation, that are controlled in part by the local host rock chemistry.

Reporting codes Gold Fields reports its Mineral resources and mineral reserves in accordance with the 2007 Samrec code, the south african codes for the reporting of mineral asset valuation (2009 Samval code) and other relevant international codes such as the united states securities and Exchange commission (sec) industry guide 7, the joint ore reserves committee (jorc 2012) Code and the national instrument (Ni) 43-101. The mineral resources and mineral reserves are underpinned by an appropriate mineral resource management process and protocol to ensure adequate corporate governance in respect of the sarbanes-oxley act.

Geological setting and mineralisation

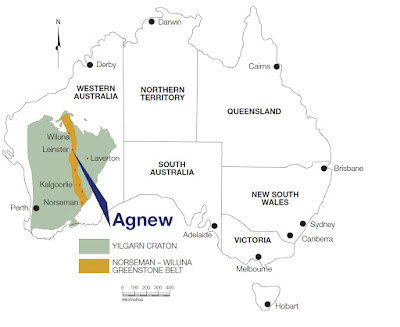

Agnew is situated in the northern portion of the Norseman- Wiluna greenstone belt, which is part of the yilgarn craton,A 2.6 ga granite greenstone terrain in Western Australia.

The rock types in the belt comprise abundant tholeiitic and Komatiitic volcanic rocks, chert, sulphidic and albiticSedimentary rocks, and a chain of discrete felsic volcanic Centres. The greenstones of the agnew area have been Metamorphosed to upper greenschist, lower amphibolite Metamorphic grades. Gold mineralisation is found in quartzBreccia lodes, quartz tensional veining and disseminated Arsenopyrite-pyrite-biotite mineralisation. This is developed along the lithological contact between a sandstone and ultramafic conglomerate and on other contacts within the ultramafic conglomerates package. High-grade ore shoots Plunge steeply to the north along these contacts. The controls on mineralisation are dilational zones at the intersection of steeply dipping north-south axial planar structures with the Stratigraphy. The stronger the contrast in rock competency in these zones, the greater the potential for mineralisation. Much of the yilgarn craton is deeply weathered and partially covered by tertiary and quaternary regolith. Pre-tertiary Lateritic horizons are variably exposed, stripped or buried by later deposits that have in turn been lateritised. The depth of Weathering is strongly controlled by original rock types, with mafic rocks generally being more susceptible to weathering than felsic rocks.

Although all of the Agnew deposits are broadly hosted by the intersections between structures and stratigraphy, there are subtle differences in alteration and mineralisation, controlled in part by the local host rock chemistry. Songvang is unusual in its relatively high lead, silver and fluorine content, possibly reflecting input from tonalite and porphyry intrusions. There also appears to have been a slight decline in mineralization temperatures from south to north through the Agnew area, associated with the north plunge of the Lawlers Anticline and resultant erosion of the overlying lower-temperature rocks to the south. This temperature change is reflected in the changing mineralisation styles from south to north, with biotite/garnet assemblages dominating to the south and quartz veining to the north. The stratigraphy of the Agnew-Wiluna belt appears to be broadly similar to the stratigraphy of the Kalgoorlie Region. The following section provides a detailed description of the general stratigraphy for the Agnew mining leases and the stratigraphic location of various ore bodies.

Mining methods

Access to the Waroonga underground mine is via a portal and decline, located in the previously mined Waroonga open pit. All primary infrastructures, including escape ways and ventilation shafts, are located in the competent sandstone of the hanging wall. The dimensions of the decline are 5.5 metres wide by 5.8 metres high, with arched backs to allow high-capacity trucks to operate.

The Rajah Lode was mined in 2012 using the modified Avoca Method. This is a variation of bench-stoping methodology where the fill typically consists of uncemented waste rock that is introduced to control wall stability at intervals from 20 to 30 metres. During 2012 the Main Lode North ore body was extracted using transverse stoping, with mining commencing at the footwall and retreating to the hangingwall. The stopes were accessed via a tramming drive developed in the hangingwall sandstone. The final northern cutback of the Songvang pit was completed in February 2012.

Mineral processing

The comminution circuit comprises a contractor-owned and operated three-stage crushing plant, feeding a fine ore stockpile, ahead of a two-stage closed circuit ball milling circuit. Milled ore proceeds to a three-stage leaching train feeding the six-stage carbon in pulp (CIP) circuit. Carbon elution is by pressure Zadra with gold being electro-won and smelted. In February 2003 a gravity circuit was retrofitted. It comprises a Knelson gravity concentrator and an intensive leach reactor (ILR) for intensive cyanidation of the gravity concentrate. The gravity circuit was upgraded and retrofitted in September 2011 to incorporate a second 26” Knelson gravity concentrator, an ILR 2000BA and two Magscreen 1000 units. The processing capacity at the plant is 1.3 Mtpa. Quantitative analysis of recovery improvements will be evaluated and included in future Mineral Resources and Mineral Reserve calculations in accordance with the grade/ recovery model currently adopted. Tailings disposal and impoundment have historically been to a conventional dam constructed using the upstream lift method sourcing wall material from dried tailings. The original tailing storage facility (TSF) was located in an area some 1.5 kilometres south-west of the Agnew plant. Deposition to this facility ceased in early 2004 and a large section of this decommissioned facility has been capped with waste rock.

The remaining exposed sections are being harvested for use as underground paste fill. Following completion of mining activities at the Redeemer Mine, the abandoned pit has been converted to a tailings storage impoundment for tailings arising from the Agnew plant (TSF3). Although situated seven kilometres south of the Agnew plant, the static head is negative, and pumping of the tailings material is therefore done at no additional cost from the previous deposition technique. The pontoon-mounted decant pump recovers water from the supernatant pond, which forms due to liberation of water from the tailings slurry as it settles and consolidates. TSF3 is projected to last until 2015, based on deposition rates of 1.3 million tonnes per annum and historical deposition levels from December 2004 to February 2011.

Mineral Resource classification

Mineral Reserve classification

Mine model of Agnew Waroonga ore body

0 komentar:

Post a Comment